The Shredding Solution for the Smooth Operation of Your Biogas Plant

Tietjen’s biomass shredder BMS is a vertical grinder that efficiently and homogeneously processes biomass for anaerobic digestion. By de-fibering, crushing and grinding with Tietjen’s BMS, a higher gas yield is achieved, and difficult substrates can be made usable in the digester.

These raw materials are typically grinded and crushed in the Biomass Shredder BMS:

- Solid manure from chickens, cattle, horses, turkeys or pigs.

Corn and grass silage

Corn and grass silage- Grass clippings and straw

- Sugar beets

- Crops and agricultural waste

- other biomass

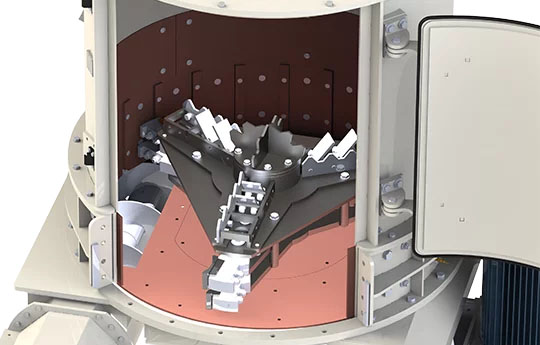

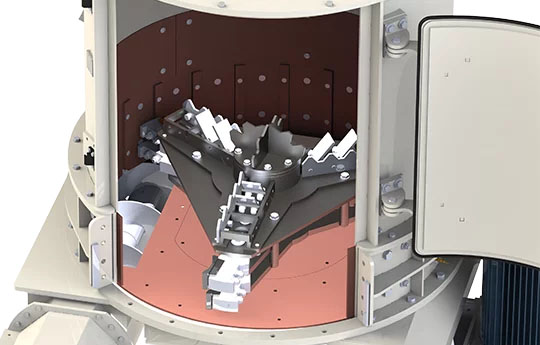

Functional principle

The biomass, such as solid manure, straw or silage, is fed into the machine from above, pre-shredded by a ripping comb above the rotor and then enters the impact zone. Shredding then takes place by means of a rapidly rotating rotor and impact bars made of wear-resistant material. The beaters mounted on the rotor provide a blunt de-fibering action, resulting in a homogeneous and well-digested substrate that is ideally prepared for anaerobic digestion.

The biomass, such as solid manure, straw or silage, is fed into the machine from above, pre-shredded by a ripping comb above the rotor and then enters the impact zone. Shredding then takes place by means of a rapidly rotating rotor and impact bars made of wear-resistant material. The beaters mounted on the rotor provide a blunt de-fibering action, resulting in a homogeneous and well-digested substrate that is ideally prepared for anaerobic digestion.

Advantages at a glance

PROBLEM SOLVER FOR BIOGAS PLANTS

- Efficient particle size reduction of even the most difficult substrates

- Flexibility and economy using alternative raw materials

- High throughput rates of up to 15 t/h (depends on substrate)

- Process optimisation through better pumping and agitating properties, minimisation of the floating layer

RELIABLE OPERATION AND LONG DURABILITY

- Robust welded construction for continuous industrial operation (24/7)

- Impact parts and beaters made of wear-resistant materials such as Hardox and tungsten carbide

- Clog-free operation due to discharge in the bottom of the impact chamber

- Resistant to impurities, as no sharp tools are used

HIGH AVAILABILITY AND EASY MAINTENANCE

- Large maintenance door with platform ensures maximum accessibility

- Position of the maintenance door can be adjusted in 90° steps to suit the conditions on site

- Minimal wear costs due to replaceable shredding tools on the beater

- Easy to change wear plates due to outside screw connection

- Easy removal of heavy parts by crane traverse with chain hoist (option)

HIGH SAFETY OF PERSONNEL AND PLANT

- Door securing with key transfer system

- Monitoring of unbalance, contaminant ingress and vibrations by means of vibration sensor

- Sensors for monitoring the bearing temperature

Corn and grass silage

Corn and grass silage The biomass, such as solid manure, straw or silage, is fed into the machine from above, pre-shredded by a ripping comb above the rotor and then enters the impact zone. Shredding then takes place by means of a rapidly rotating rotor and impact bars made of wear-resistant material. The beaters mounted on the rotor provide a blunt de-fibering action, resulting in a homogeneous and well-digested substrate that is ideally prepared for anaerobic digestion.

The biomass, such as solid manure, straw or silage, is fed into the machine from above, pre-shredded by a ripping comb above the rotor and then enters the impact zone. Shredding then takes place by means of a rapidly rotating rotor and impact bars made of wear-resistant material. The beaters mounted on the rotor provide a blunt de-fibering action, resulting in a homogeneous and well-digested substrate that is ideally prepared for anaerobic digestion.